Anchor Plates and Systems

At Anchor Systems International Ltd, we provide a wide range of high-quality anchoring solutions that use a variety of termination plates in order to meet the unique requirements of your projects.

Our plates are available in bespoke shapes, sizes, and materials, ensuring they can be used for many specific applications across slope stabilisation, retaining walls, heritage conservation, and beyond. Below, you’ll find detailed descriptions of our most popular solutions.

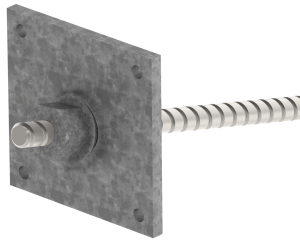

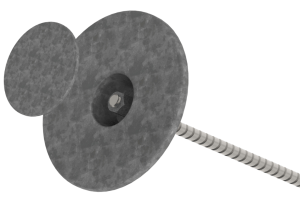

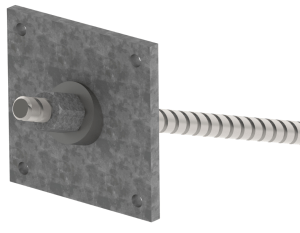

Formed Pattress Plate

Formed Pattress Plates are designed for retaining walls and slope stabilisation, offering a high degree of flexibility in installation angles. These plates are paired with Domed Load Nuts to securely terminate the anchor bar.

Formed Pattress Plates are designed for retaining walls and slope stabilisation, offering a high degree of flexibility in installation angles. These plates are paired with Domed Load Nuts to securely terminate the anchor bar.

Features:

- Bespoke shapes and sizes available.

- High flexibility for angle adjustments.

Applications:

- Retaining walls.

- Slope stabilisation requiring varied installation angles.

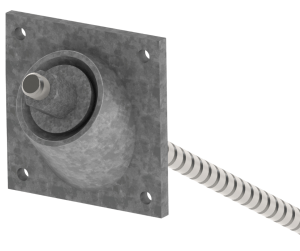

Recessed Pattress Plate

The Recessed Pattress Plate is ideal for projects where aesthetics are critical. It offers a flush-finished appearance with hidden terminations, making it perfect for heritage sites and high-traffic areas where safety and appearance are paramount.

The Recessed Pattress Plate is ideal for projects where aesthetics are critical. It offers a flush-finished appearance with hidden terminations, making it perfect for heritage sites and high-traffic areas where safety and appearance are paramount.

Features:

- Flush finish for a clean aesthetic.

- Hidden terminations for safety and design integrity.

Applications:

- Heritage and conservation works.

- Public areas where safety is essential.

Wedge Boss Pattress Plate

The Wedge Boss Pattress Plate provides high load transfer while allowing anchors to be driven at angles of up to 45 degrees. Its flexibility makes it suitable for challenging installations.

The Wedge Boss Pattress Plate provides high load transfer while allowing anchors to be driven at angles of up to 45 degrees. Its flexibility makes it suitable for challenging installations.

Features:

- Supports angled installations up to 45 degrees.

- High load transfer capability.

Applications:

- Complex anchoring projects requiring angled flexibility.

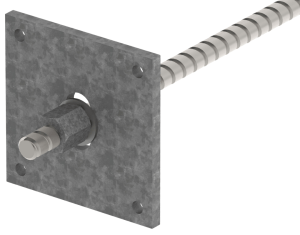

Flat Pattress Plate

Flat Pattress Plates are versatile solutions designed primarily for slope stabilisation where anchors are driven perpendicular to the surface. However, they can also accommodate angled installations when paired with tapered washers. These plates can be secured using either bars with load nuts or wires with barrel and wedge grips.

Features:

- Bespoke shapes and sizes available.

- Compatible with a variety of Vulcan anchor sizes.

- Flexible for angled requirements with tapered washers.

Applications:

- Slope stabilisation projects.

- Infrastructure requiring secure anchoring.

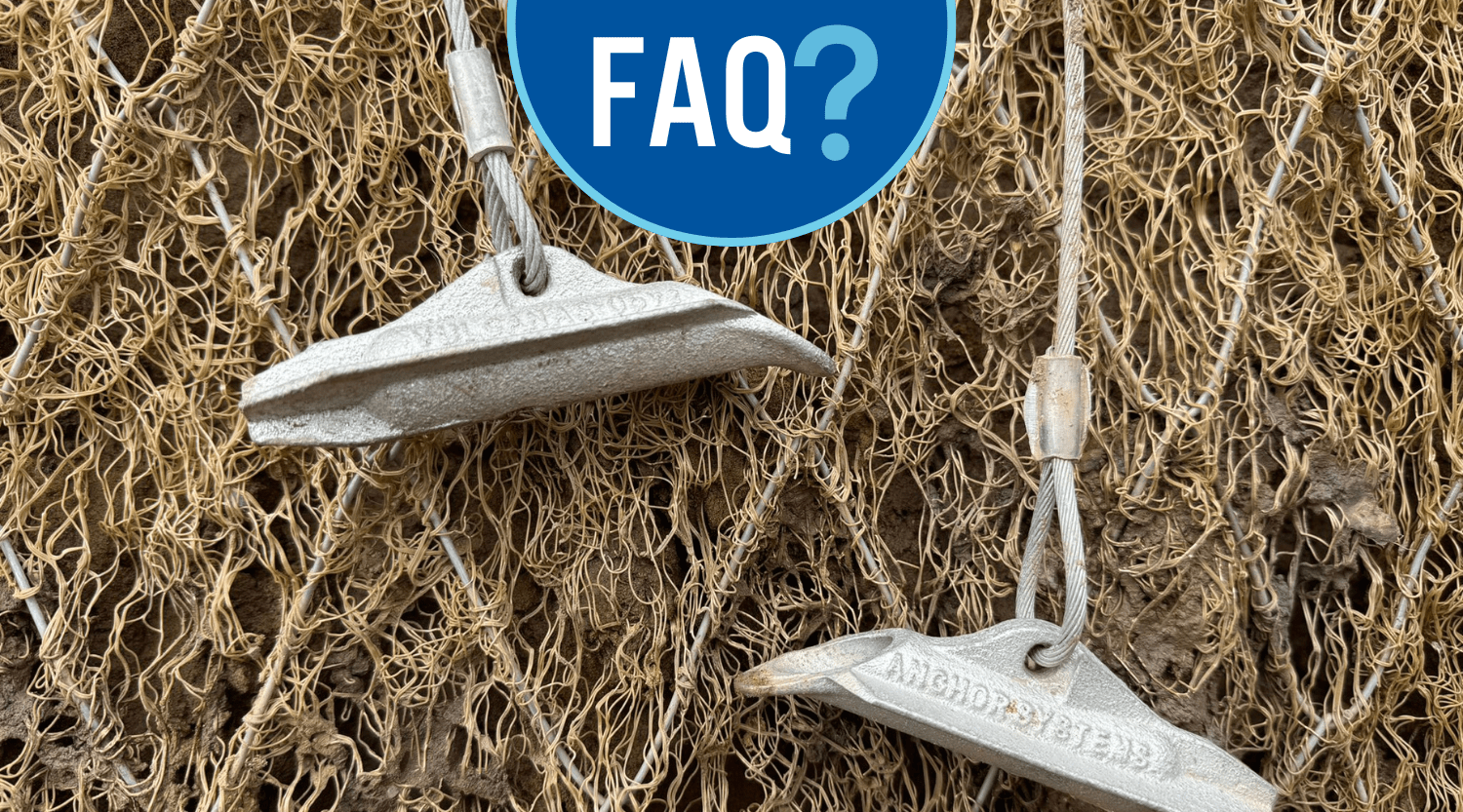

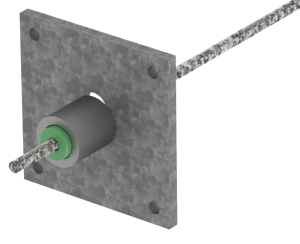

Flat Pattress Plate with Wire

This variant of the Flat Pattress Plate replaces the lock nut with a barrel and wedge grip, allowing for use with wire instead of bar. This design offers additional flexibility for projects requiring different anchoring methods with smaller loads or shorter install depths.

This variant of the Flat Pattress Plate replaces the lock nut with a barrel and wedge grip, allowing for use with wire instead of bar. This design offers additional flexibility for projects requiring different anchoring methods with smaller loads or shorter install depths.

Features:

- Bespoke shapes and sizes available.

- Flexible securing options using wire systems.

Applications:

- Projects requiring adaptable anchoring techniques.

Tapered Washer Pattress Plate

Tapered Washers are used with Flat Pattress Plates for applications requiring flexible installation angles for up to 20 degrees and can support high load capacities.

Tapered Washers are used with Flat Pattress Plates for applications requiring flexible installation angles for up to 20 degrees and can support high load capacities.

Features:

- Designed for high-load applications.

- Allows for angled installations when paired with Flat Pattress Plates.

Applications:

- Projects requiring both flexibility and strength.

Combi-Tech Anchor

The Combi-Tech Anchor System is specifically designed for stabilising damaged masonry structures, making it ideal for heritage, listed building renovations, and refurbishment projects. Its concealed top termination preserves the original appearance of structures, ensuring compliance with aesthetic and planning constraints.

The Combi-Tech Anchor System is specifically designed for stabilising damaged masonry structures, making it ideal for heritage, listed building renovations, and refurbishment projects. Its concealed top termination preserves the original appearance of structures, ensuring compliance with aesthetic and planning constraints.

Benefits:

- Simple, efficient installation.

- Reduces the need for grout and additional materials.

- High-strength performance.

- Customisable to any length, fitting up to 90mm core holes.

- Testing equipment readily available.

Applications:

- Heritage conservation.

- Masonry stabilisation for historic and listed buildings.

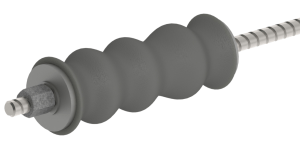

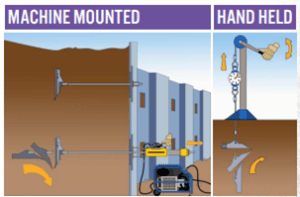

Vulcan Anchor Drain

The Vulcan Anchor Drain system addresses water pressure in slopes or retaining walls through a retro-fit drainage membrane. It utilises a length of Mem?braDrain wicking material secured to the Vulcan anchor head, ensuring immediate drainage and slope stability upon installation.

Features:

- Instantly reduces water pressure and prevents ground saturation.

- Rapid and cost-effective installation.

- Retro-fit solution for embankment stability.

- Finished with mortar pointing or a bespoke plate design.

Applications:

- Road and railway embankments.

- Retaining walls and slope stabilisation.

Benefits:

- Helps prevent embankment failure.

- Relieves puddle pressure.

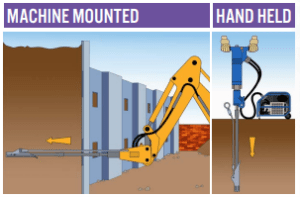

- Suitable for installation with handheld or machine equipment.

Why Choose Our Solutions?

- Bespoke: All plates and systems can be tailored to your project’s specifications.

- Durable: Manufactured from high-quality materials for long-lasting performance.

- Innovative: Advanced designs ensure safety, flexibility, and efficiency.

- Supportive: Our expert team is ready to assist with technical advice and testing solutions.

Contact Us

Need help choosing the right plate or system for your project? Get in touch with our team today for personalised advice and recommendations. Call us on 01342 719 362 or send us an enquiry via our contact form.

FAQ: How Is The Load Distributed On The Anchors?

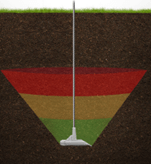

The load distribution on Vulcan Earth Anchors is a multi-stage process that involves both the anchor system and the surrounding soil. The following explains how the load is distributed during installation and load application:

Initial load application

In the first stage, a force is applied to rotate the anchor into its load-locked position. This process involves both loading and the extension of the anchor system. The design of the Vulcan Earth Anchor ensures precise engagement with the soil, allowing for secure anchorage and minimal disturbance to the surrounding area.

Compaction and loading

During the second stage, the anchor system begins compacting the soil in front of the anchor, forming a conical shape. This compaction increases the soil’s resistance, enhancing the system’s stability. At this stage, the load on the anchor typically increases with minimal extension. The type and condition of the soil—whether compacted, loose, or gravelly—play a significant role in determining the total extension and compaction efficiency.

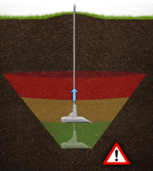

Peak load range

In the third stage, the anchor reaches its maximum load capacity. At this point, the soil’s bearing capacity becomes the limiting factor. As the load approaches this limit, the rate of load increase diminishes. The design of Vulcan Earth Anchors ensures consistent performance across varying soil conditions, offering reliable results even as the soil approaches its bearing capacity.

Nearing capacity failure

IMPORTANT: If the soil’s mechanical shear strength is exceeded, bearing capacity failure may occur. When this happens, the load on the anchor diminishes as the anchor begins to extend further, shearing through the soil. Proper soil analysis and anchor selection are critical to preventing failure and optimising performance.

Additional Considerations

- Soil Type Impact: The performance of Vulcan Earth Anchors can vary based on the type of soil, such as clay, sand, or gravel. These factors are carefully evaluated during project planning to ensure the appropriate anchor and installation method are chosen.

- Design Optimisation: Engineers can distribute loads across multiple anchors or adjust the anchor layout to account for soil variability, reducing the risk of overloading any single anchor.

By understanding these stages and soil mechanics, Vulcan Earth Anchors provide reliable, high-capacity solutions for stabilising slopes, retaining walls, and infrastructure in challenging environments.

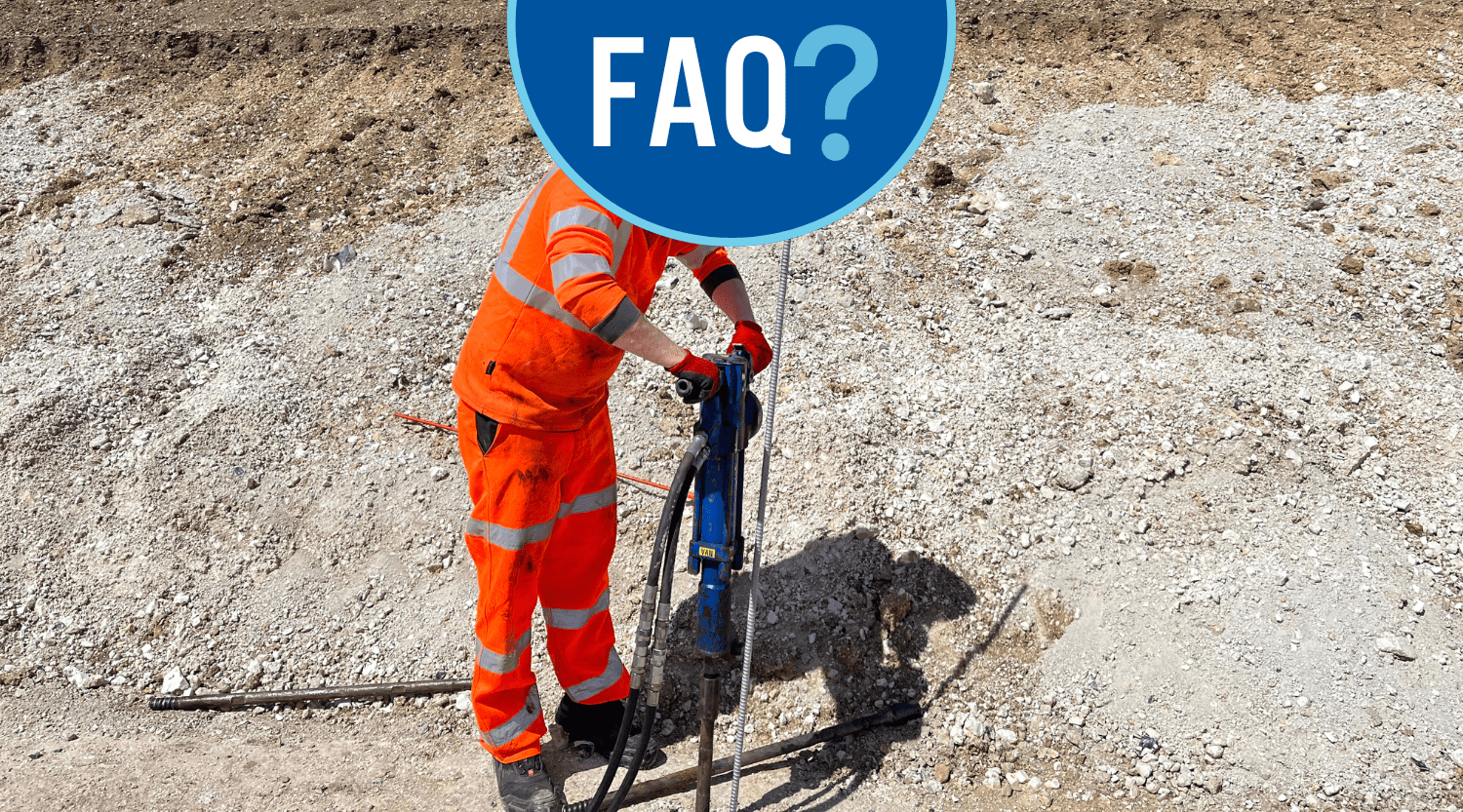

FAQ: Can You Really Install The Anchors By Hand?

Yes! Vulcan Earth Anchors are engineered for versatility and ease of installation. These anchors can be driven into the ground using hydraulic or percussion equipment, with minimal disruption to the surrounding structure or area. For smaller anchors, such as those in the AS-01 to AS-50 range, installation can often be completed by hand using brute force or lightweight hydraulic handheld tools.

When specifying the appropriate Vulcan Earth Anchor for your project, we will consider factors such as access to the wall, slope, or structure to ensure the most suitable installation method is selected. For projects requiring larger anchors or higher load capacities, such as anchors installed with percussion equipment, we work closely with the project designer to identify solutions if access is restricted.

For instance, if installation of a larger anchor proves challenging, we may recommend adjusting the anchor centres or increasing the number of anchors to distribute the load effectively. This approach ensures optimal performance while accommodating site-specific constraints.

Whether you’re working on a slope stabilisation project, retaining wall, or securing infrastructure in a challenging location, Vulcan Earth Anchors offer flexible and efficient installation options tailored to your project needs.

Why Choose Anchor Systems?

Our expertise in ground anchoring solutions, including Vulcan Earth Anchors, ensures every project receives tailored support and the highest quality standards. Whether you need a design for stabilising slopes or anchoring critical infrastructure, we’re here to help.

Additional Resources

If you’re looking for more information on Earth Anchors, their applications, or the design process, explore our Vulcan Earth Anchor Product Page or contact our experts at Anchor Systems International Ltd. Our team is here to guide you in selecting the best anchoring solution for your project. Call us today at 01342 719362 or email us at info@anchorsystems.co.uk to discuss your requirements or request a free consultation.

FAQ: Do You Offer a Design Service?

At Anchor Systems, we take pride in delivering comprehensive support and a first-class service that sets us apart from competitors. From the initial enquiry to project completion, our goal is to ensure our clients’ needs are fully met.

Our Process

The journey begins with understanding your objectives and preferred working methods. We offer full guidance and support throughout the design and ordering process, continuing even after the goods are delivered. Our commitment doesn’t end there—we provide ongoing support, training, and on-site supervision to ensure complete satisfaction at every stage.

We also specialise in creating bespoke designs tailored to the unique requirements of your project, offering solutions that perfectly align with your needs.

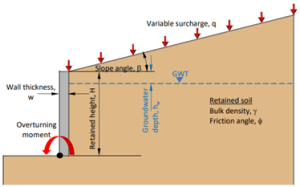

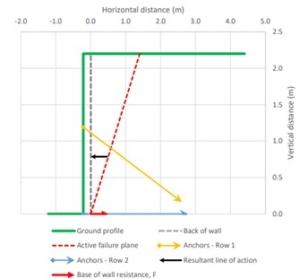

Stability Designs

We offer two types of stability design commonly used for retaining walls, embankments, and slope stabilisation.

- Local Stability Design

- This design is based on the loading requirements, drawings, and soil investigation data provided by the principal engineer.

- Using this information, we assess the specific soil conditions and recommend the appropriate ground anchors and their layout to ensure stability.

-

Global Stability Analysis Design

-

- For this design, the principal engineer provides the necessary drawings, a factor of safety, and detailed soil investigation data.

- Based on these inputs, we calculate the load requirements of each earth anchor to maintain the desired level of stability.

Both designs are developed using recognised calculation methods and industry standards such as Eurocodes, DMRB, and CIRIA guidelines. We provide the results in a detailed PDF report, and a signed design certificate can be included if required.

It’s important to note that if the overall design includes a structure, a qualified structural engineer must ensure its adequacy.

Why Choose Anchor Systems?

Our expertise in ground anchoring solutions, including Vulcan Earth Anchors, ensures every project receives tailored support and the highest quality standards. Whether you need a design for stabilising slopes or anchoring critical infrastructure, we’re here to help.

Additional Resources

If you’re looking for more information on Earth Anchors, their applications, or the design process, explore our Vulcan Earth Anchor Product Page or contact our experts at Anchor Systems International Ltd. Our team is here to guide you in selecting the best anchoring solution for your project. Call us today at 01342 719362 or email us at info@anchorsystems.co.uk to discuss your requirements or request a free consultation.