Cable Route Management, Cockfosters Depot

- CLIENT : Transport for London

- DESIGNER : Arcadis

- CONTRACTORS : Spoortech

- INSTALLER : Site 7

REQUIREMENT

As part of Transport for London’s Piccadilly Line Upgrade, around 450m of a new Cable Route Management System (CRMS) was required at Cockfosters Depot to support additional track installations there. A faster, more cost-effective, and environmentally friendly alternative to traditional CRMS that is concreted in place was asked for, and Anchor Systems’ CRMS which is approved for use on the LU network for up to 16 cable hangers (8-way back-to-back) was an ideal solution.

Minimal site preparation was necessary and mostly included vegetation clearance and levelling. While no pre-installation soil testing was needed due to a conservative design approach that assumed poor conditions, post-installation load testing was performed on 1 in 25 pairs of Anchor Screws using pull tests, and all of the tested Anchor Screws passed and even exceeded required load capacities, confirming compliance with TfL standards.

SOLUTION

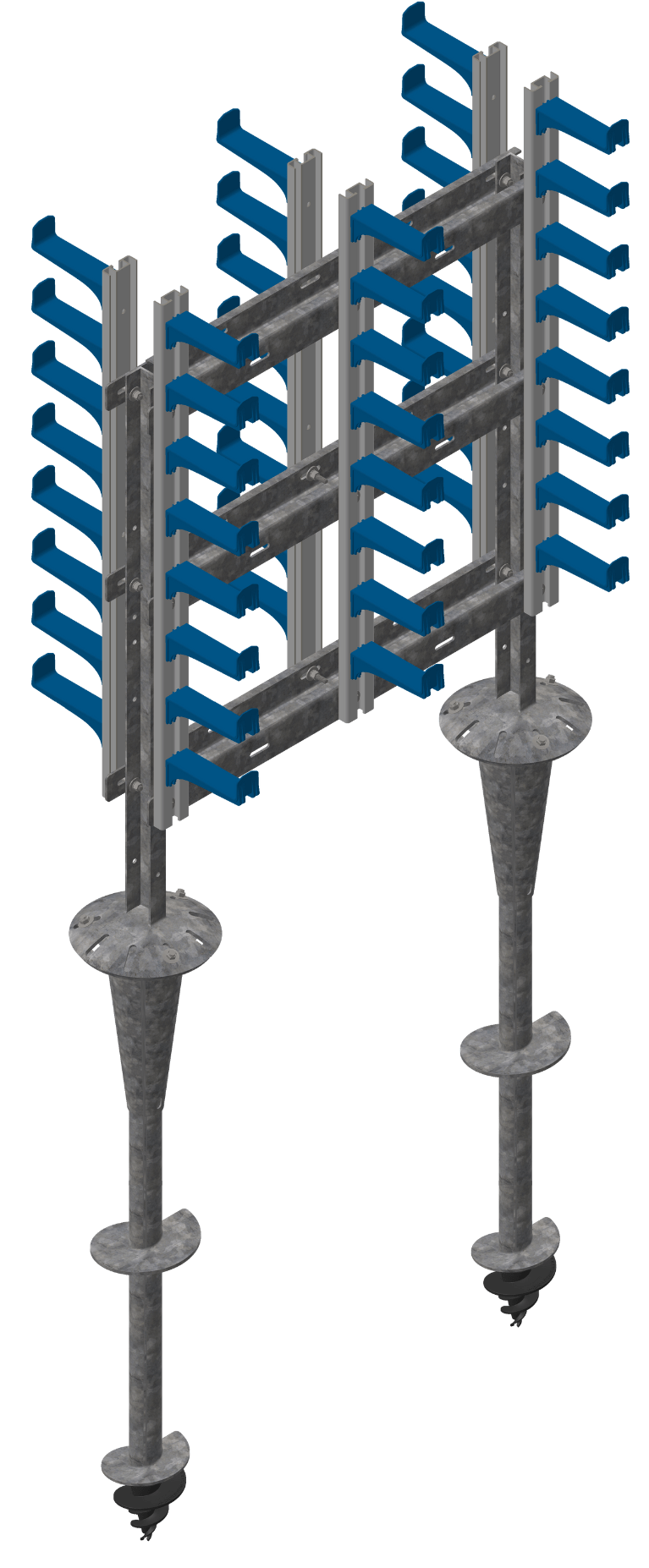

The system used 1795mm Anchor Screws at 1.2m spacing, supporting 1.4m cable posts joined together by Horizontal Span Rails. These rails also supported GRP backplates at 0.6m centres, which GRP hangers were then mounted to in order to support the cables. By using the GRP backplate and hangers it added a touch-safe/non-conductive element and increased the safety of the system.

A total of 359 Anchor Screws were installed, with an additional 40 added later for where underground obstructions were found. In these instances, the spacing of the Anchor Screws was widened to 2.4m centres, and 1995mm screws were used in order to remain compliant with testing standards.

Most of the Anchor Screws were installed using a machine mounted torque head (600X) as there was plenty of space to work with on site, and the Anchor Screws were being installed in a relatively straight line, making the machine mounted option the obvious choice. In some of the harder to access areas, handheld equipment was used (400H) to install the Anchor Screws. The remainder of the system was assembled by hand using handheld power tools to tighten up all the fixings.

RESULT

The installed Cable Route Management System exceeded expectations in both performance and ease of installation, as well as providing a real-world case study showing the difference in speed and efficiency of our CRMS compared to traditional install methods and existing systems.

Anchor Systems delivered a reliable, adaptable, and standard-compliant solution under challenging conditions and tight timelines, and with the success of Phase 1 led to a direct invitation from Transport for London to design and supply CRMS for Phase 2 of the Cockfosters Depot upgrade, extending the system by an additional 700 metres.

Overall, the project demonstrated the versatility and efficiency of Anchor Systems’ ground anchoring solutions, reinforcing our position as a trusted partner in critical rail infrastructure projects.