Brighton Mainline DAS Systems

- CLIENT : BAM Nuttall

- CONSULTANT : JNP

- INSTALLER : CRS & BAM

REQUIREMENT

The Brighton Mainline DAS (Distributed Antenna System) installation project was commissioned by BAM Nuttall as part of a significant rail infrastructure upgrade. The objective was to install approximately 50 stages and grillages to support 5G antenna masts and accompanying cabinets. Given the critical role of these structures in enhancing connectivity along the railway, the installation required a robust and reliable foundation system that could be efficiently deployed in precise locations with minimal disruption to railway operations.

Several key challe nges needed to be addressed, including:

nges needed to be addressed, including:

- Limited Site Access: The work had to be carried out within restricted railway possession times, making material transportation and the installation time sensitive.

- Ground Variability: The project spanned from Balham to Brighton, with increasingly challenging ground conditions such as chalk requiring a versatile foundation solution.

- Sloped Installation Sites: Many locations required tailored solutions for flat, up-bank, and down-bank ground conditions to ensure stability and safety.

To overcome these challenges, a screw pile foundation system was chosen due to its rapid installation process, high load-bearing capacity, it’s ability to be adapted to different site conditions, and minimal environmental impact compared to traditional concrete foundations.

Testing

Before installation, a series of site investigations were conducted to assess the suitability of the foundation system for the sites. Although no direct load testing was performed, geotechnical surveys provided critical data to guide the installation process. Ground Penetrating Radar (GPR) and coordinate mapping were used to identify subsurface conditions and detect any potential obstructions. Additionally, a Geotechnical Investigation (GI) confirmed that the ground conditions were suitable for the installation of screw piles at the recommended installation depths.

The Ground Design Report (GDR) outlined the essential installation requirements, including the minimum torque values and depth criteria necessary to achieve structural integrity. Based on these findings, it was determined that the screw piles needed to reach a minimum depth of 3 metres OR achieve a torque value of 1.5 kNm during installation. This assessment provided confidence that the chosen foundation system would perform effectively across all designated installation sites.

SOLUTION

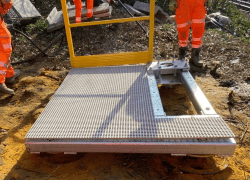

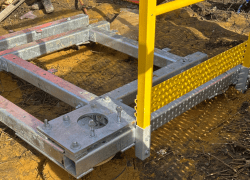

To meet the project’s structural requirements, Anchor Systems supplied and installed 3-4 metre screw pile arrangements. Each installation consisted of a 2-metre 76R Triple Lead Screw Pile, extended as needed with either one or more 1-metre 76R extensions. At the top of each pile, a 350mm pile adaptor was fitted to support the stagings/grillages and allow them to be levelled and set in the right position. A steel grillage with a section of grating and handrail was used at flat ground sites, whereas a full GRP stage with handrail and gates/ladders were used at sloping sites.

Installation Process

The screw piles were installed using a 700H Torque Head with a reaction arm to ensure precision and stability. Prior to installation, 1-metre trial pits were dug to verify the absence of underground services, ensuring a safe and effective deployment before these pits were then backfilled with self-compacting fill.