Anchor Plates and Systems

At Anchor Systems International Ltd, we provide a wide range of high-quality anchoring solutions that use a variety of termination plates in order to meet the unique requirements of your projects.

Our plates are available in bespoke shapes, sizes, and materials, ensuring they can be used for many specific applications across slope stabilisation, retaining walls, heritage conservation, and beyond. Below, you’ll find detailed descriptions of our most popular solutions.

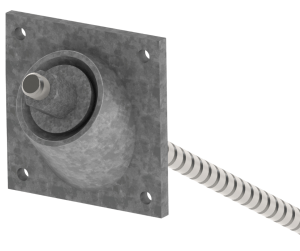

Formed Pattress Plate

Formed Pattress Plates are designed for retaining walls and slope stabilisation, offering a high degree of flexibility in installation angles. These plates are paired with Domed Load Nuts to securely terminate the anchor bar.

Formed Pattress Plates are designed for retaining walls and slope stabilisation, offering a high degree of flexibility in installation angles. These plates are paired with Domed Load Nuts to securely terminate the anchor bar.

Features:

- Bespoke shapes and sizes available.

- High flexibility for angle adjustments.

Applications:

- Retaining walls.

- Slope stabilisation requiring varied installation angles.

Recessed Pattress Plate

The Recessed Pattress Plate is ideal for projects where aesthetics are critical. It offers a flush-finished appearance with hidden terminations, making it perfect for heritage sites and high-traffic areas where safety and appearance are paramount.

The Recessed Pattress Plate is ideal for projects where aesthetics are critical. It offers a flush-finished appearance with hidden terminations, making it perfect for heritage sites and high-traffic areas where safety and appearance are paramount.

Features:

- Flush finish for a clean aesthetic.

- Hidden terminations for safety and design integrity.

Applications:

- Heritage and conservation works.

- Public areas where safety is essential.

Wedge Boss Pattress Plate

The Wedge Boss Pattress Plate provides high load transfer while allowing anchors to be driven at angles of up to 45 degrees. Its flexibility makes it suitable for challenging installations.

The Wedge Boss Pattress Plate provides high load transfer while allowing anchors to be driven at angles of up to 45 degrees. Its flexibility makes it suitable for challenging installations.

Features:

- Supports angled installations up to 45 degrees.

- High load transfer capability.

Applications:

- Complex anchoring projects requiring angled flexibility.

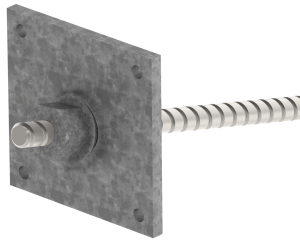

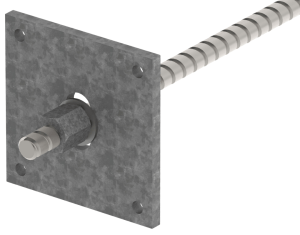

Flat Pattress Plate

Flat Pattress Plates are versatile solutions designed primarily for slope stabilisation where anchors are driven perpendicular to the surface. However, they can also accommodate angled installations when paired with tapered washers. These plates can be secured using either bars with load nuts or wires with barrel and wedge grips.

Features:

- Bespoke shapes and sizes available.

- Compatible with a variety of Vulcan anchor sizes.

- Flexible for angled requirements with tapered washers.

Applications:

- Slope stabilisation projects.

- Infrastructure requiring secure anchoring.

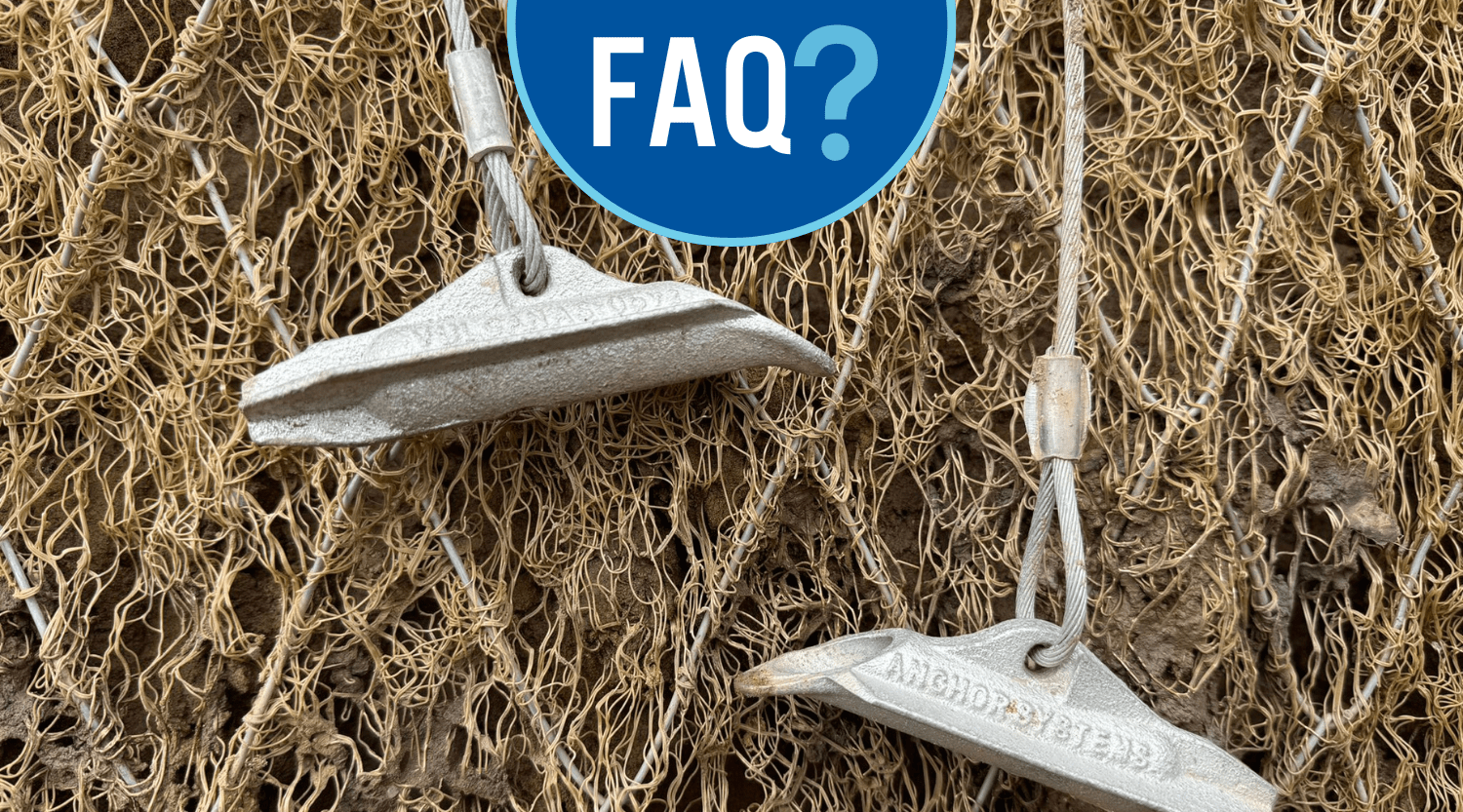

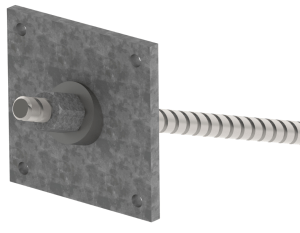

Flat Pattress Plate with Wire

This variant of the Flat Pattress Plate replaces the lock nut with a barrel and wedge grip, allowing for use with wire instead of bar. This design offers additional flexibility for projects requiring different anchoring methods with smaller loads or shorter install depths.

This variant of the Flat Pattress Plate replaces the lock nut with a barrel and wedge grip, allowing for use with wire instead of bar. This design offers additional flexibility for projects requiring different anchoring methods with smaller loads or shorter install depths.

Features:

- Bespoke shapes and sizes available.

- Flexible securing options using wire systems.

Applications:

- Projects requiring adaptable anchoring techniques.

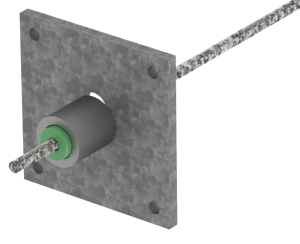

Tapered Washer Pattress Plate

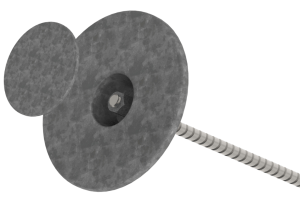

Tapered Washers are used with Flat Pattress Plates for applications requiring flexible installation angles for up to 20 degrees and can support high load capacities.

Tapered Washers are used with Flat Pattress Plates for applications requiring flexible installation angles for up to 20 degrees and can support high load capacities.

Features:

- Designed for high-load applications.

- Allows for angled installations when paired with Flat Pattress Plates.

Applications:

- Projects requiring both flexibility and strength.

Combi-Tech Anchor

The Combi-Tech Anchor System is specifically designed for stabilising damaged masonry structures, making it ideal for heritage, listed building renovations, and refurbishment projects. Its concealed top termination preserves the original appearance of structures, ensuring compliance with aesthetic and planning constraints.

The Combi-Tech Anchor System is specifically designed for stabilising damaged masonry structures, making it ideal for heritage, listed building renovations, and refurbishment projects. Its concealed top termination preserves the original appearance of structures, ensuring compliance with aesthetic and planning constraints.

Benefits:

- Simple, efficient installation.

- Reduces the need for grout and additional materials.

- High-strength performance.

- Customisable to any length, fitting up to 90mm core holes.

- Testing equipment readily available.

Applications:

- Heritage conservation.

- Masonry stabilisation for historic and listed buildings.

Vulcan Anchor Drain

The Vulcan Anchor Drain system addresses water pressure in slopes or retaining walls through a retro-fit drainage membrane. It utilises a length of Mem?braDrain wicking material secured to the Vulcan anchor head, ensuring immediate drainage and slope stability upon installation.

Features:

- Instantly reduces water pressure and prevents ground saturation.

- Rapid and cost-effective installation.

- Retro-fit solution for embankment stability.

- Finished with mortar pointing or a bespoke plate design.

Applications:

- Road and railway embankments.

- Retaining walls and slope stabilisation.

Benefits:

- Helps prevent embankment failure.

- Relieves puddle pressure.

- Suitable for installation with handheld or machine equipment.

Why Choose Our Solutions?

- Bespoke: All plates and systems can be tailored to your project’s specifications.

- Durable: Manufactured from high-quality materials for long-lasting performance.

- Innovative: Advanced designs ensure safety, flexibility, and efficiency.

- Supportive: Our expert team is ready to assist with technical advice and testing solutions.

Contact Us

Need help choosing the right plate or system for your project? Get in touch with our team today for personalised advice and recommendations. Call us on 01342 719 362 or send us an enquiry via our contact form.

FAQ: How Is The Load Distributed On The Anchors?

The load distribution on Vulcan Earth Anchors is a multi-stage process that involves both the anchor system and the surrounding soil. The following explains how the load is distributed during installation and load application:

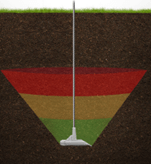

Initial load application

In the first stage, a force is applied to rotate the anchor into its load-locked position. This process involves both loading and the extension of the anchor system. The design of the Vulcan Earth Anchor ensures precise engagement with the soil, allowing for secure anchorage and minimal disturbance to the surrounding area.

Compaction and loading

During the second stage, the anchor system begins compacting the soil in front of the anchor, forming a conical shape. This compaction increases the soil’s resistance, enhancing the system’s stability. At this stage, the load on the anchor typically increases with minimal extension. The type and condition of the soil—whether compacted, loose, or gravelly—play a significant role in determining the total extension and compaction efficiency.

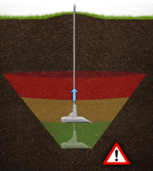

Peak load range

In the third stage, the anchor reaches its maximum load capacity. At this point, the soil’s bearing capacity becomes the limiting factor. As the load approaches this limit, the rate of load increase diminishes. The design of Vulcan Earth Anchors ensures consistent performance across varying soil conditions, offering reliable results even as the soil approaches its bearing capacity.

Nearing capacity failure

IMPORTANT: If the soil’s mechanical shear strength is exceeded, bearing capacity failure may occur. When this happens, the load on the anchor diminishes as the anchor begins to extend further, shearing through the soil. Proper soil analysis and anchor selection are critical to preventing failure and optimising performance.

Additional Considerations

- Soil Type Impact: The performance of Vulcan Earth Anchors can vary based on the type of soil, such as clay, sand, or gravel. These factors are carefully evaluated during project planning to ensure the appropriate anchor and installation method are chosen.

- Design Optimisation: Engineers can distribute loads across multiple anchors or adjust the anchor layout to account for soil variability, reducing the risk of overloading any single anchor.

By understanding these stages and soil mechanics, Vulcan Earth Anchors provide reliable, high-capacity solutions for stabilising slopes, retaining walls, and infrastructure in challenging environments.

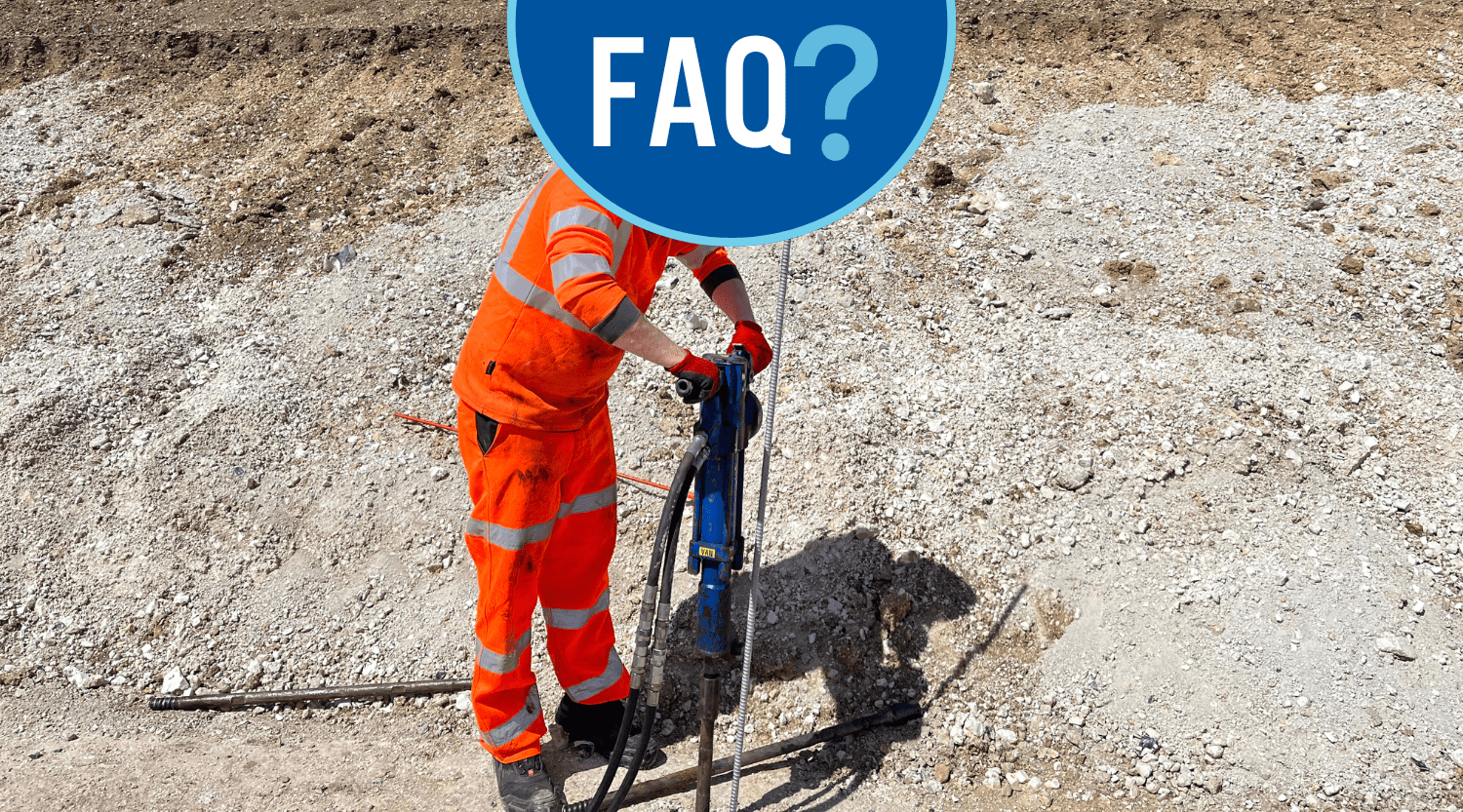

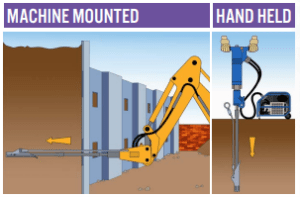

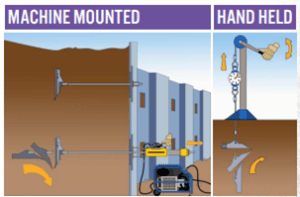

FAQ: Can You Really Install The Anchors By Hand?

Yes! Vulcan Earth Anchors are engineered for versatility and ease of installation. These anchors can be driven into the ground using hydraulic or percussion equipment, with minimal disruption to the surrounding structure or area. For smaller anchors, such as those in the AS-01 to AS-50 range, installation can often be completed by hand using brute force or lightweight hydraulic handheld tools.

When specifying the appropriate Vulcan Earth Anchor for your project, we will consider factors such as access to the wall, slope, or structure to ensure the most suitable installation method is selected. For projects requiring larger anchors or higher load capacities, such as anchors installed with percussion equipment, we work closely with the project designer to identify solutions if access is restricted.

For instance, if installation of a larger anchor proves challenging, we may recommend adjusting the anchor centres or increasing the number of anchors to distribute the load effectively. This approach ensures optimal performance while accommodating site-specific constraints.

Whether you’re working on a slope stabilisation project, retaining wall, or securing infrastructure in a challenging location, Vulcan Earth Anchors offer flexible and efficient installation options tailored to your project needs.

Why Choose Anchor Systems?

Our expertise in ground anchoring solutions, including Vulcan Earth Anchors, ensures every project receives tailored support and the highest quality standards. Whether you need a design for stabilising slopes or anchoring critical infrastructure, we’re here to help.

Additional Resources

If you’re looking for more information on Earth Anchors, their applications, or the design process, explore our Vulcan Earth Anchor Product Page or contact our experts at Anchor Systems International Ltd. Our team is here to guide you in selecting the best anchoring solution for your project. Call us today at 01342 719362 or email us at info@anchorsystems.co.uk to discuss your requirements or request a free consultation.

FAQ: Do You Offer a Design Service?

At Anchor Systems, we take pride in delivering comprehensive support and a first-class service that sets us apart from competitors. From the initial enquiry to project completion, our goal is to ensure our clients’ needs are fully met.

Our Process

The journey begins with understanding your objectives and preferred working methods. We offer full guidance and support throughout the design and ordering process, continuing even after the goods are delivered. Our commitment doesn’t end there—we provide ongoing support, training, and on-site supervision to ensure complete satisfaction at every stage.

We also specialise in creating bespoke designs tailored to the unique requirements of your project, offering solutions that perfectly align with your needs.

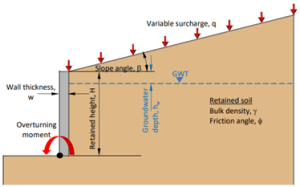

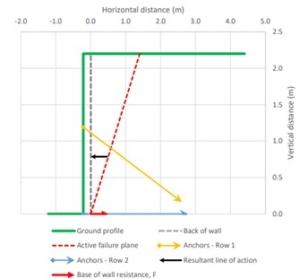

Stability Designs

We offer two types of stability design commonly used for retaining walls, embankments, and slope stabilisation.

- Local Stability Design

- This design is based on the loading requirements, drawings, and soil investigation data provided by the principal engineer.

- Using this information, we assess the specific soil conditions and recommend the appropriate ground anchors and their layout to ensure stability.

-

Global Stability Analysis Design

-

- For this design, the principal engineer provides the necessary drawings, a factor of safety, and detailed soil investigation data.

- Based on these inputs, we calculate the load requirements of each earth anchor to maintain the desired level of stability.

Both designs are developed using recognised calculation methods and industry standards such as Eurocodes, DMRB, and CIRIA guidelines. We provide the results in a detailed PDF report, and a signed design certificate can be included if required.

It’s important to note that if the overall design includes a structure, a qualified structural engineer must ensure its adequacy.

Why Choose Anchor Systems?

Our expertise in ground anchoring solutions, including Vulcan Earth Anchors, ensures every project receives tailored support and the highest quality standards. Whether you need a design for stabilising slopes or anchoring critical infrastructure, we’re here to help.

Additional Resources

If you’re looking for more information on Earth Anchors, their applications, or the design process, explore our Vulcan Earth Anchor Product Page or contact our experts at Anchor Systems International Ltd. Our team is here to guide you in selecting the best anchoring solution for your project. Call us today at 01342 719362 or email us at info@anchorsystems.co.uk to discuss your requirements or request a free consultation.

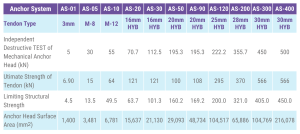

FAQ: How Is The Structural Strength of a Vulcan Earth Anchor System Determined?

The Vulcan Earth Anchor

All parts of a Vulcan Earth Anchor System are checked through independent testing. The weakest component’s break load is then reduced by a further 10% and recorded as the Limiting Structural Strength of that anchor system.

This capacity is usually far beyond what the soil will allow the anchor to achieve so, in some cases, especially in well compacted soils or gravel layers, the anchors achieve high loads allowing the designers to use smaller anchors to achieve the design load required, therefore, offering the most cost-effective solution.

The Vulcan Earth Anchor range has been carefully designed and been named based on the holding capacity achieved in medium to poor soil conditions. E.G. an AS-90 anchor supplied on a 20mm galvanised bar system has a limiting structural strength of 169.2kN. However, in medium to poor soil conditions this anchor will achieve a maximum capacity of 90kN. Anchors that are installed into stiffer substrates they will exceed their named loads.

*All kN loadings are based upon the optimal tendon choice for the mechanical Anchoring systems to achieve Ultimate Resistance test*.

Ensuring Accuracy in Anchor Design

To achieve optimal performance, several factors are considered during the design and installation process:

- Soil Testing: Comprehensive soil analysis helps determine the substrate type and its shear strength.

- Anchor Selection: Engineers select the appropriate anchor model and bar system based on project requirements and soil conditions.

- Installation Method: Proper installation is critical to maximise the anchor’s performance and ensure long-term stability.

Sustainability and Longevity

Vulcan Earth Anchors are manufactured using high-quality, recyclable materials, contributing to sustainable construction practices. Their durability ensures a long operational lifespan, reducing the need for replacements and minimising environmental impact.

By combining robust testing, intelligent design, and versatile performance, the Vulcan Earth Anchor System delivers reliable, cost-effective solutions for a wide range of ground anchoring challenges.

Additional Resources

If you’re looking for more information on Earth Anchors, their applications, or the design process, explore our Vulcan Earth Anchor Product Page or contact our experts at Anchor Systems International Ltd. Our team is here to guide you in selecting the best anchoring solution for your project. Call us today at 01342 719362 or email us at info@anchorsystems.co.uk to discuss your requirements or request a free consultation.

FAQ: What Factors Determine The Design Life Of An Earth Anchor?

Several factors influence the design life of an Earth Anchor, determining how long it can safely and effectively perform its function. Earth Anchors are critical for soil stabilisation and stabilising structures in various applications, including construction, railways, landscaping, and infrastructure projects. By choosing the right ground anchor system, you can ensure the long-term stability of your project.

Key Factors Impacting Earth Anchor Design Life

Material Properties

Corrosion Resistance

The material type, such as steel, galvanized steel, or corrosion-resistant coatings, significantly impacts its lifespan. In aggressive environments like marine or acidic soils, corrosion reduces the anchor’s effective life. For marine anchors or those used in industrial environments, using corrosion-resistant anchors is critical to maintaining performance over time.

Strength of Materials:

The tensile strength, fatigue resistance, and durability of materials directly affect the anchor’s ability to withstand loads over time. High-strength steel or composite materials are commonly used for structural support anchors that require superior durability.

Soil Conditions

Soil Type and Composition

Different soils, including clay, sand, and rock, vary in their capacity to hold Earth Anchors. The design life depends on the anchor’s ability to maintain adequate holding capacity in the given soil type. Ground Anchors are designed to work across various soil conditions for soil stabilisation.

Soil Moisture and pH

Moisture content and the pH level of the soil can influence corrosion rates and soil-structure interactions. Wet, acidic, or alkaline soils can cause faster degradation of the anchor materials.

Environmental Exposure

Groundwater Levels

Rising or fluctuating groundwater levels can impact the stability of the Earth Anchor and accelerate material degradation. This can significantly reduce the design life of anchors used in infrastructure anchoring solutions.

Chemical Exposure:

In industrial or marine environments, exposure to chemicals like saltwater and pollutants accelerates material corrosion, shortening the anchor’s service life. For marine anchoring solutions, using corrosion-resistant materials is crucial.

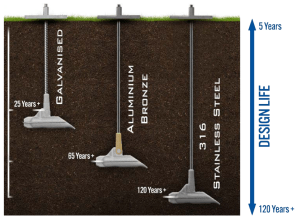

Custom Design Life Solutions for Earth Anchors

The client’s designer usually specifies the design life, and we recommend a tailored solution after considering these factors. We manufacture Earth Anchoring Systems from high-quality, recyclable materials, ensuring a design life ranging from 5 to 120+ years. Our Vulcan Earth Anchors and other ground anchors typically include fully galvanised options, mixtures of galvanised materials, aluminium bronze, stainless steel, or complete 316 stainless steel systems. Whether you need permanent or temporary anchors, we provide sustainable anchoring systems for any project.

Additional Resources

If you’re looking for more information on Earth Anchors, their applications, or the design process, explore our Vulcan Earth Anchor Product Page or contact our experts at Anchor Systems International Ltd. Our team is here to guide you in selecting the best anchoring solution for your project. Call us today at 01342 719362 or email us at info@anchorsystems.co.uk to discuss your requirements or request a free consultation.

Work Experience at Anchor Systems

Last week we welcomed Barney for some Work Experience. Over his three days here he delved into both our Vulcan mechanical anchors and our Anchor Screws, as well as gaining insights into specifications and applications. Barney got the chance to try hands-on assembly and equipment use, plus vital tasks like stock counting and warehouse organisation. We’re all wishing Barney the best of luck as he pursues a level 1 Vocational Engineering course at Chichester College. If you or someone you know is looking for some Work Experience, get in contact with us today!

[gallery ids="3627,3628,3629,3630"]Introducing the Anchor Screw Brochure

Hot off the press and just landed at Anchor Systems HQ is our brand new Anchor Screw brochure! Download it now.

Our patented Anchor Screw is an easy to install foundation solution that has enhanced environmental benefits compared to it’s alternatives.

This system was designed and evolved from the needs of some Network Rail projects that required to improve both the efficiency and sustainability of their standard construction materials and methods.

The Anchor Screw eradicates the need to use concrete and is made in Britain from 100% recycled UK steel. It can also be made with a 100+ year lifespan making it economical as well sustainable.

You can see the system in use in these two project reports:

Hither Green Signalling Renewal Project

Westbourne Park Segregation Barrier Project

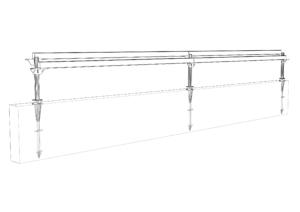

Benefits and Features

-

Speed

Typically installed in under 10 minutes per anchor -

Easy to Install

Zero on-track plant or RRV’s required as installed with lightweight, handheld equipment - Dust

Zero dust is generated as no cementitious products required - Environmental

Fully reusable and Made in Britain from UK recycled steel - Longevity

Can be designed with 50 or 100+ year lifespans dependant on client requirements - Water and Drying Times

Zero water consumed or drying time required, as no wet trades involved - HAVS

Zero risk as the installation equipment is non-percussive - Noise

Installation is relatively quiet. The installation equipment runs at 80-85db - Versatility

Easily adjustable to guarantee the correct positioning with patented design features - Mess and Waste Materials

Zero mess due to no digging required nor any general wasted materials, which reduce manhours and project risks

You can download the brochure here: Download Now

Or if you would like to book a CPD presentation for you and your team or get your hands on a physical copy then pop us an email: info@anchorsystems.co.uk

Are you still using concrete?

Did you know that concrete is the most destructive material on Earth?

It is the most widely used man-made material in existence. It is second only to water as the most-consumed resource on the planet. In an ever-changing world where we are trying to reduce our carbon footprint, we are overlooking one of the biggest causes. Concrete is said to be responsible for around 8% of the world’s CO2 emissions. We have focused largely over the past several years on reducing our plastic use, yet all the plastic produced over the past 60 years amounts to 8bn tonnes, the cement industry pumps out more than that every two years.

We are not saying never use concrete. There is a place for concrete until we find something else that compares with it without the negative impact on the environment. But why use concrete unnecessarily?

When looking at foundation systems, instead of digging up vast areas of earth and filling them with concrete, look at alternatives.

The Anchor Post and Anchor Screw are made up from 100% recycled British steel, do not require any concrete to hold them in place and there is no digging required or removing of the soil. As there is no concrete there is no drying time and installations can be completed in a single visit. The unique dome head allows for adjustments to be made easily and simply. Bespoke interface plates can be designed to suit each individual application.

On a recent project with Balfour Beatty and Network Rail (see here), our system was used instead of concrete and the below results were recorded:

- 60 per cent time saving on foundation installation

- 40 per cent cost saving of £369 per metre to £221 per metre (derived from man hour savings, elimination of plant requirements, reduced possession requirements)

- 73 per cent embodied carbon reduction on materials, equivalent to 13,920kg CO2e and 89.4 per cent material saving

- Zero on-track plant and zero water consumed

- UK manufacturing and local materials, eliminating mainland European transportation miles

If you would like to find out more about the Anchor Post or Anchor Screw and how it can eradicate the need for concrete and make your next project a more sustainable one, then please email us or contact us on 01342 719 362.

You can also download our brochures here.

Sources:

https://www.bbc.co.uk/news/science-environment-46455844

https://www.theguardian.com/cities/2019/feb/25/concrete-the-most-destructive-material-on-earth

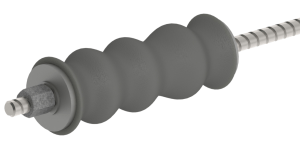

What Is a Vulcan Earth Anchor?

A Vulcan Earth Anchor® is a percussion driven mechanical ground anchor. It can also be referred to as an Earth Anchor or Percussion Anchor.

A Vulcan Earth Anchor® is a percussion driven mechanical ground anchor. It can also be referred to as an Earth Anchor or Percussion Anchor.

Vulcan Earth Anchors are used as a cost effective and rapidly installed system to provide a positive force on a verity or projects.

The Vulcan Earth Anchor range was designed by Anchor Systems (International) Ltd as a simple, reliable and cost-effective ground anchoring solution with the ability to provide immediate loading capacities from 1 – 450kN in displaceable ground conditions with extensive applications.

The concept involves a specially designed earth anchor with a larger surface area, attached to high yield tie bars or tendons to suit a variety of conditions, being driven into the ground where it is locked in position. The tensile load is applied, and the exposed end locked off and terminated.

With their ease of use and speed of installation, Vulcan Earth Anchors provide a time and cost saving alternative to more traditional means of anchoring, particularly where tight programme schedules are involved. This combined with the wide range of sizes available means that the Vulcan Earth Anchor has gained recognition across a vast array of applications internationally.

Benefits:

- Larger surface area allowing the Vulcan Earth Anchor to achieve the greatest holding capacity in all ground conditions

- Rapid installation

- Largest range of anchors in the World ranging from 1 – 450kN+

- We are the only company globally to manufacture and stock fully stainless-steel systems

- Bespoke design available

- Huge stock of plant and products with next day delivery available

- Made in Britain

If you would like more details on our Vulcan Earth Anchor you can view our brochure or email us.

[gallery slick_active="true" sl_centermode="true" ids="2732,2675,2646,2604,2493,2453,2445,2378,1849,1818,1819,1815,1820,1560,1550"]