Anchor Plates and Systems

At Anchor Systems International Ltd, we provide a wide range of high-quality anchoring solutions that use a variety of termination plates in order to meet the unique requirements of your projects.

Our plates are available in bespoke shapes, sizes, and materials, ensuring they can be used for many specific applications across slope stabilisation, retaining walls, heritage conservation, and beyond. Below, you’ll find detailed descriptions of our most popular solutions.

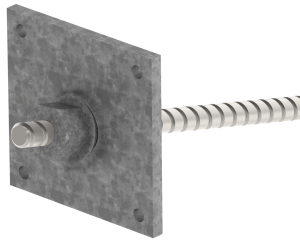

Formed Pattress Plate

Formed Pattress Plates are designed for retaining walls and slope stabilisation, offering a high degree of flexibility in installation angles. These plates are paired with Domed Load Nuts to securely terminate the anchor bar.

Formed Pattress Plates are designed for retaining walls and slope stabilisation, offering a high degree of flexibility in installation angles. These plates are paired with Domed Load Nuts to securely terminate the anchor bar.

Features:

- Bespoke shapes and sizes available.

- High flexibility for angle adjustments.

Applications:

- Retaining walls.

- Slope stabilisation requiring varied installation angles.

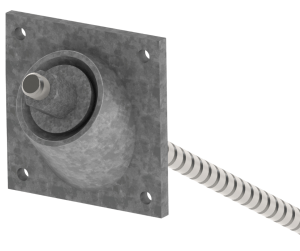

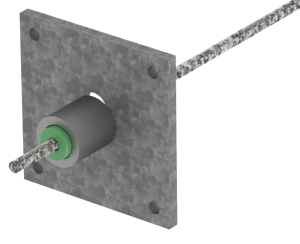

Recessed Pattress Plate

The Recessed Pattress Plate is ideal for projects where aesthetics are critical. It offers a flush-finished appearance with hidden terminations, making it perfect for heritage sites and high-traffic areas where safety and appearance are paramount.

The Recessed Pattress Plate is ideal for projects where aesthetics are critical. It offers a flush-finished appearance with hidden terminations, making it perfect for heritage sites and high-traffic areas where safety and appearance are paramount.

Features:

- Flush finish for a clean aesthetic.

- Hidden terminations for safety and design integrity.

Applications:

- Heritage and conservation works.

- Public areas where safety is essential.

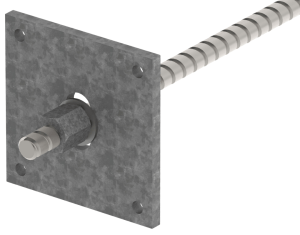

Wedge Boss Pattress Plate

The Wedge Boss Pattress Plate provides high load transfer while allowing anchors to be driven at angles of up to 45 degrees. Its flexibility makes it suitable for challenging installations.

The Wedge Boss Pattress Plate provides high load transfer while allowing anchors to be driven at angles of up to 45 degrees. Its flexibility makes it suitable for challenging installations.

Features:

- Supports angled installations up to 45 degrees.

- High load transfer capability.

Applications:

- Complex anchoring projects requiring angled flexibility.

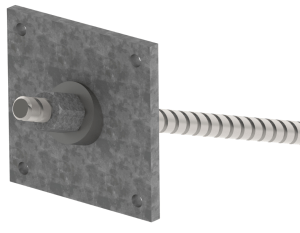

Flat Pattress Plate

Flat Pattress Plates are versatile solutions designed primarily for slope stabilisation where anchors are driven perpendicular to the surface. However, they can also accommodate angled installations when paired with tapered washers. These plates can be secured using either bars with load nuts or wires with barrel and wedge grips.

Features:

- Bespoke shapes and sizes available.

- Compatible with a variety of Vulcan anchor sizes.

- Flexible for angled requirements with tapered washers.

Applications:

- Slope stabilisation projects.

- Infrastructure requiring secure anchoring.

Flat Pattress Plate with Wire

This variant of the Flat Pattress Plate replaces the lock nut with a barrel and wedge grip, allowing for use with wire instead of bar. This design offers additional flexibility for projects requiring different anchoring methods with smaller loads or shorter install depths.

This variant of the Flat Pattress Plate replaces the lock nut with a barrel and wedge grip, allowing for use with wire instead of bar. This design offers additional flexibility for projects requiring different anchoring methods with smaller loads or shorter install depths.

Features:

- Bespoke shapes and sizes available.

- Flexible securing options using wire systems.

Applications:

- Projects requiring adaptable anchoring techniques.

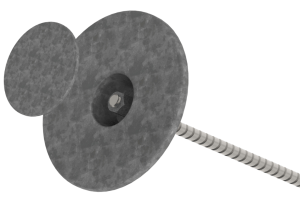

Tapered Washer Pattress Plate

Tapered Washers are used with Flat Pattress Plates for applications requiring flexible installation angles for up to 20 degrees and can support high load capacities.

Tapered Washers are used with Flat Pattress Plates for applications requiring flexible installation angles for up to 20 degrees and can support high load capacities.

Features:

- Designed for high-load applications.

- Allows for angled installations when paired with Flat Pattress Plates.

Applications:

- Projects requiring both flexibility and strength.

Combi-Tech Anchor

The Combi-Tech Anchor System is specifically designed for stabilising damaged masonry structures, making it ideal for heritage, listed building renovations, and refurbishment projects. Its concealed top termination preserves the original appearance of structures, ensuring compliance with aesthetic and planning constraints.

The Combi-Tech Anchor System is specifically designed for stabilising damaged masonry structures, making it ideal for heritage, listed building renovations, and refurbishment projects. Its concealed top termination preserves the original appearance of structures, ensuring compliance with aesthetic and planning constraints.

Benefits:

- Simple, efficient installation.

- Reduces the need for grout and additional materials.

- High-strength performance.

- Customisable to any length, fitting up to 90mm core holes.

- Testing equipment readily available.

Applications:

- Heritage conservation.

- Masonry stabilisation for historic and listed buildings.

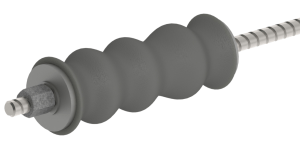

Vulcan Anchor Drain

The Vulcan Anchor Drain system addresses water pressure in slopes or retaining walls through a retro-fit drainage membrane. It utilises a length of Mem?braDrain wicking material secured to the Vulcan anchor head, ensuring immediate drainage and slope stability upon installation.

Features:

- Instantly reduces water pressure and prevents ground saturation.

- Rapid and cost-effective installation.

- Retro-fit solution for embankment stability.

- Finished with mortar pointing or a bespoke plate design.

Applications:

- Road and railway embankments.

- Retaining walls and slope stabilisation.

Benefits:

- Helps prevent embankment failure.

- Relieves puddle pressure.

- Suitable for installation with handheld or machine equipment.

Why Choose Our Solutions?

- Bespoke: All plates and systems can be tailored to your project’s specifications.

- Durable: Manufactured from high-quality materials for long-lasting performance.

- Innovative: Advanced designs ensure safety, flexibility, and efficiency.

- Supportive: Our expert team is ready to assist with technical advice and testing solutions.

Contact Us

Need help choosing the right plate or system for your project? Get in touch with our team today for personalised advice and recommendations. Call us on 01342 719 362 or send us an enquiry via our contact form.

What Is a Vulcan Earth Anchor?

A Vulcan Earth Anchor® is a percussion driven mechanical ground anchor. It can also be referred to as an Earth Anchor or Percussion Anchor.

A Vulcan Earth Anchor® is a percussion driven mechanical ground anchor. It can also be referred to as an Earth Anchor or Percussion Anchor.

Vulcan Earth Anchors are used as a cost effective and rapidly installed system to provide a positive force on a verity or projects.

The Vulcan Earth Anchor range was designed by Anchor Systems (International) Ltd as a simple, reliable and cost-effective ground anchoring solution with the ability to provide immediate loading capacities from 1 – 450kN in displaceable ground conditions with extensive applications.

The concept involves a specially designed earth anchor with a larger surface area, attached to high yield tie bars or tendons to suit a variety of conditions, being driven into the ground where it is locked in position. The tensile load is applied, and the exposed end locked off and terminated.

With their ease of use and speed of installation, Vulcan Earth Anchors provide a time and cost saving alternative to more traditional means of anchoring, particularly where tight programme schedules are involved. This combined with the wide range of sizes available means that the Vulcan Earth Anchor has gained recognition across a vast array of applications internationally.

Benefits:

- Larger surface area allowing the Vulcan Earth Anchor to achieve the greatest holding capacity in all ground conditions

- Rapid installation

- Largest range of anchors in the World ranging from 1 – 450kN+

- We are the only company globally to manufacture and stock fully stainless-steel systems

- Bespoke design available

- Huge stock of plant and products with next day delivery available

- Made in Britain

If you would like more details on our Vulcan Earth Anchor you can view our brochure or email us.

[gallery slick_active="true" sl_centermode="true" ids="2732,2675,2646,2604,2493,2453,2445,2378,1849,1818,1819,1815,1820,1560,1550"]

Anchor Systems on Site

We have been looking back at the behind the scenes and onsite work that we have been doing over the last year. Offering everything from in person and online CPD Presentations, design of products, installation and on-site training.

CPD Presentations

Want to learn more about our products and find out how they can save you time and money on your next project?

Our CPD presentations explain how our products work, the benefits of using them and also how you could utilise them in your upcoming projects. We have a choice of different topics and can offer live online presentations and face to face presentations when social distancing is relaxed.

Click here to find out more or book your CPD presentation.

Design

We work with several Consultant Engineers that support us in providing fully indemnified designs for your projects whilst taking into account the most cost-effective solutions.

We work with several Consultant Engineers that support us in providing fully indemnified designs for your projects whilst taking into account the most cost-effective solutions.

When deciding which systems to use on your projects we will always look at conducting a site test so we can be sure that you get the correct product needed and will determine what plant is required for you to complete the job.

Find out more in-depth information about our design process

Training & On-Site Support

We offer bespoke training for our entire product and plant range which can take place either at our head office in West Sussex or on site. This training will then allow your team to install our products themselves which depending on the size of your project could save you a significant amount of money.

We offer bespoke training for our entire product and plant range which can take place either at our head office in West Sussex or on site. This training will then allow your team to install our products themselves which depending on the size of your project could save you a significant amount of money.

As well as training and design, our on-site support has always been a key service to our clients. We can offer additional advice on site as well toolbox talks and site specific advice, we usually attend for the first day(s) of the installation just to offer some tips and advice and make sure that everyone installing is happy in a practical setting with handling the anchors and equipment. Click here for further information.

Installation and Plant Hire

If you would like a complete supply and installation, then we have our very own list of trained and trusted list approved installers who we can arrange to install for you.

If you would like to install yourself and have taken advantage of our training, then we can supply all the plant equipment that you will need to install our products. This equipment can either be hired or purchased directly though us.

Find out more about our plant hire.

If you would like any advice, support, or have any questions about how we could help on your next project please get in touch.

Email: info@anchorsystems.co.uk

Tel: 01342 719 362

[gallery slick_active="true" sl_centermode="true" ids="2592,2591,2590,2589,2588,2587,2586,2585,2584,2583,2582,2581,2580,2579,2578,2577,2576,2575,2574"]